Harnesses

How technology and yarn go hand in hand

Experience and tradition, your certainty for high speed production!

The knowledge gained over 80 years, gave us the ability to create complete pre-levelled harnesses for every weave application.

We offer customized solutions for your challenges!

Long Experience

Customized Solutions

High Quality

COMPLETELY IN HOUSE PRODUCED PRE-LEVELLED HARNESSES FOR EVERY WEAVE APPLICATION

Security - certainty - service - quality - profit

Full service from levelling to heddle and reed drawing-in available

Customer Consultancy Service for special harness requests

Solutions for all technical and leno fabrics

Your challenge is our mainspring

Product tour

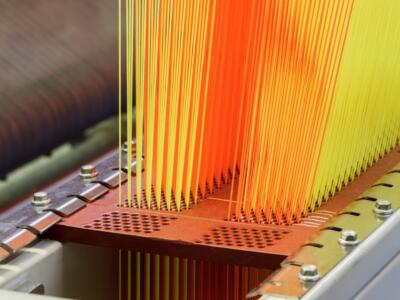

Solidity cords

- Excellent stability

- Low friction and long life-time

- Anti-dust and anti-static characteristics

- Available in a range of versions and colours

- Suitable for all weave applications

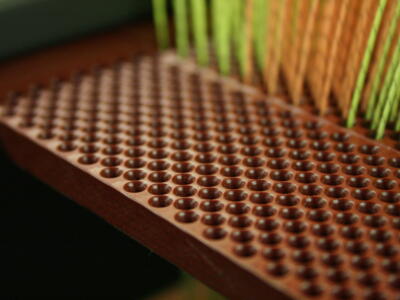

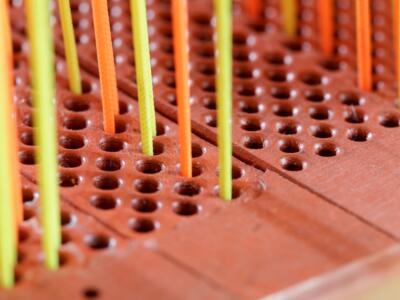

Comber board

- Drilling dimensioned for optimized contact surface

- Extra surface treatment reduces friction

- Enhanced dust-proofing and wear resistance

- Joint development of Vandewiele and Bonas

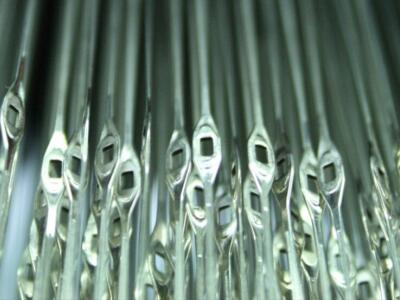

Heddles

- Optimized heddle eye for specific warp yarns

- Surface treatment for lowest friction

- Total quality control

Springs

- Reliable at any speed

- Anti-vibration

- Continuous production control

- Optimized spring load

- Low energy consumption

High density & high speed

- Recognized for high-density products and handling the most delicate yarns

- Best components for maximum efficiency at high speed

MDA

- Reduced vibrations due to high-inertia design

- Improved cooling

- Easy placement of boards without drilling

- Simple and exact alignment of the boards

- Easy access and fast cleaning

- Joint Vandewiele - Bonas development

Specialist in leno harnesses

- Decades of experience

- Up to 12 knots per cm

- Unique shed regulations

- In-house production

Questions?

Submit your data and you will be contacted by one of our experts